Phased Array Ultrasonic Testing of Flaw in Rotary Shafts

To detect a flaw in mainly stress-concentrated area

Constantly stressed, it is often occurred that flaws generate or increase by a fatigue failure in rotary shafts i.e. axles or shafts. In a driven machinery, fatigue failure is generated chiefly at stepped part, thread part or spline.

Therefore, particular attention to a generation of stress concentration in that areas is required.

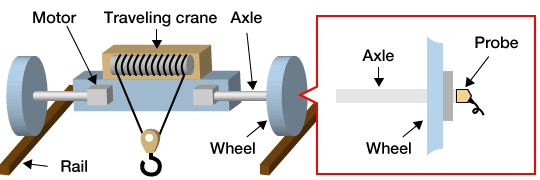

On usual maintenance inspection, you have to take a rotary shaft from a case and inspect defetcs in near the surface or aperture. But it costs a great deal of time and money because this method needs takedown of the machinery. In addition, you cannot determine how the flaw has increased on this inspection.

We provides the technology of Phased Array Ultrasonic Testing (PA-UT for short) for detecting the flaw and determining how it has increased in a shaft without unnecessary takedown, inspecting from edge of a shaft.

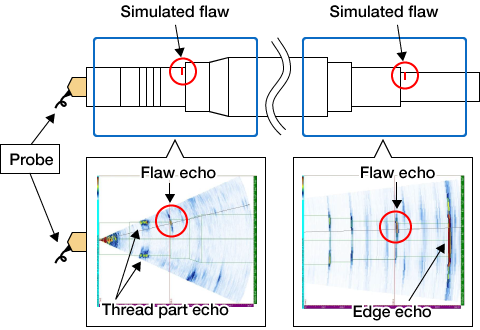

On conventional ultrasonic testing, a probe emit ultrasonic beams in a fixed direction. When the angle between emitted beams and planar-shaped flaw is nearly horizontal, flaw detectability is low. PA-UT enables you to deflect the ultrasonic waves in various direction and focus it at arbitrary distance from surface of the object by controlling the timing of emission from phased array probe, which is made up of multiple small elements. As a result, flaw detectability becomes improved. In addition, a visual image made from multiple ultrasonic waves is indicated like a search-light through the examined object while detecting the flaws, so you can discern between signal from the flaws and that from configuration if the object structure is complicated.

Magnetic Resonance Imaging (MRI for short) is well-known technique using PA-UT. In the 1970s, this technique was introduced in the medical field. The person is positioned within a cylinder-shaped MRI scanner that uses a strong magnetic field around the area to be imaged to form pictures of anatomy of the body. After that, PA-UT is developed for the maintenance inspection of the field of nuclear energy in EU and US, and in recent years it is used in the industrial field thanks to the progress of computer technology.