Example of Inspection : Infrared Thermography

FeaturesDetecting local wastage effectively without any preparation

- This enables inspection Separately, and Quickly.

- The results are represented in 2D.

- This method can be used for Operating Equipments.

AdvantagesBasically, additional work is unnecessary so it can be used for Operating Equipments.

- Significant Cost Savings because of no additional works.

- Less Oversight because of 2D-indicated results.

- You can note the important areas where the maintenance required at regular checks because this can be used for operating equipments.

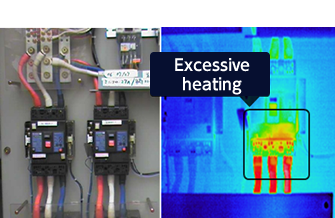

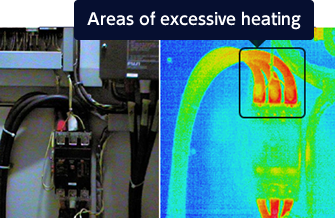

Application 1Poorly fitting contacts or connections on control panels

- Loose connection at terminal

Poorly fitting contacts

- Identify the cause for excessive heating from thermal gradient

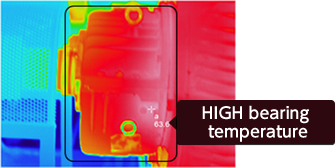

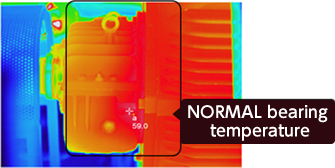

Application 2Abnormality in motor bearing

- Motor A

- Temperature A > B due to something abnormal in motor A

- Motor B

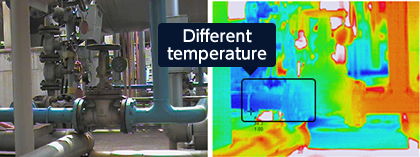

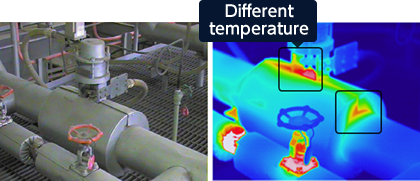

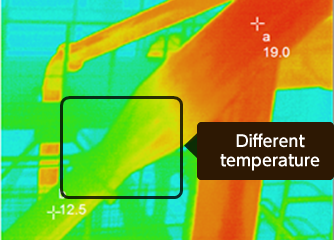

Application 3Valve Seat Leaks / Lagging Abrasion

- Valve seat leaks

- The temperature of downstream area in pipes becomes different from other areas because of valve seat leaks.

- Lagging abrasion

- Applied for the examlnation for energy loss.

Application 4Detecting the Pipe Occlusion

- Thermogram of pipe occlusion

- Detecting the position of occlusion from temperature distribution in pipes.