SH-67

Measuring the induction hardened layer depth without cutting products

The "SH-67" is device for Non-Destructive measurement of induction hardened layer depth.

You can skip conventional processes such as cutting, etching, and measuring your products by the use of "SH-67".

It makes High Efficiency and Cost Savings.

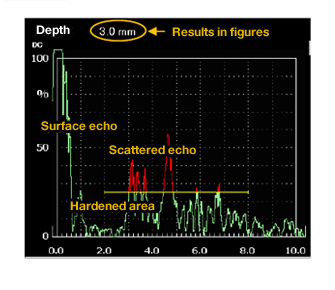

The "SH-67" is an innovative device using ultrasonic waves to measure the depth of the hardened layer, and displaying the measured results in figures on the screen .

Results are derived from the strength of scattered echo in the hardened layer and the non-hardened layer.

We propose the most suitable probe and measuring condition depending on your products.

Our high-resolution convergent probe enables you to distinguish the boundary between the hardened layer and the base metal layer distinctively.

The "SH-67" is widely used for measurement of induction hardened layer depth.

For example, automotive parts, construction machinery, machining tools, internal combustion engine, agricultural machinery and various industrial machinery.

The followings are strong advantage of us.

Measuring the induction hardened layer depth without cutting

This non-destructive measuring method makes labor savings and cost savings, then accomplish high efficiency.

Specialized knowledge - Unnecessary

We propose the measuring condition and set up the device depending on your products specification, so any expertise is unnecessary.

Field of application

- car building

- shipbuilding

- machinery and equipment

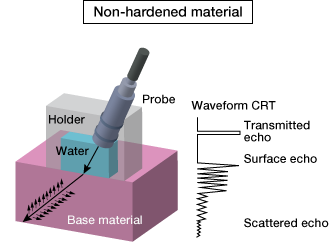

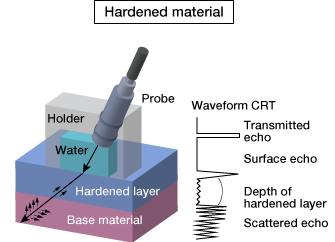

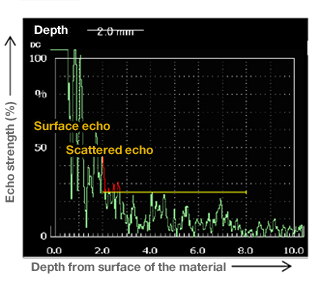

Measurement Principle

The "SH-67" employs ultrasonic waves to measure the depth of the induction hardened layer.

The hardened layer has a finer and uniformized metallographic texture than the base metal layer below it, so ultrasonic waves pass through the hardened layer. As a result, scattered echo is weak.

Whereas ultrasonic waves reach the base metal layer, then scattered echo is strong because of its non-hardened rough texture.

Observing the scattered echo as a rising edge of the waveform, which comes from the base metal layer, you can distinguish the boundary position between the hardened layer and the base metal layer.

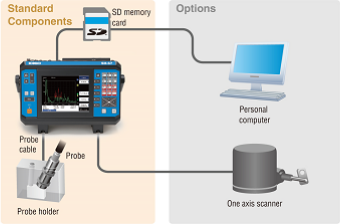

| Standard Components | |

|---|---|

| SH-67: | 1 |

| Probe (for SH-67): | 1 |

| Probe holder (standard): | 1 (An additional fee may be required to customize the probe holder.) |

| Probe cable and other attachments: | 1 set |

| Battery: | 1 |

| AC adapter: | 1 |

| SD memory card: | 1 |

| item | performance | ||

|---|---|---|---|

| SH-67 | Object to be measured | Depth of the induction hardened layer | |

| Measurement range | 0.7 to 15mm | ||

| Measurement resolution | 0.1mm | ||

| Measurement repeatability | ±0.1mm (per one location) | ||

| Scanner interface | lncluded (the scanner is optional.) | ||

| Ultrasonic testing instrument | Sensibility | 80 dB or more (5MHz narrow band) | |

| Adjustable gain | 110 dB with 0.1 dB pitch | ||

| Center frequency and bandwidth | 0.25/0.5/1/2/3/4/5/10/15/20/25MHz | ||

| Amplification linearity | ±3% or less | ||

| Test range | 1 to 14,556mm (longitudinal mode in steel) | ||

| Display time-base linearity | ±1% or less | ||

| AC adapter | AC100 to 240V±10%, 50/60Hz±3Hz, Power consumption: approx. 20W | ||

| Battery | Lithium-ion battery | ||

| Battery operating time | Approx. 8 hrs (Operating time is subject to the operation condition and ambient temperature.) | ||

| Ambient temperature | 0 to 40℃ during operation, -20 to 60℃ during storage | ||

| Display and screen size | 6.5" TFT color LCD (Super luminosity LED liquid crystal display) | ||

| External dimensions(mm), Mass(kg) | 286(W)×180(H)×110(D) (not including the projection), 3.5kg (including a battery) | ||

| Case | Waterproof and dustproof standard: Compliance with IP66. Made of reinforced ABS resin (front and back) and aluminum alloy (midsection) | ||

| External interface | Card slot | SD memory card | |

| Connector | USB (master/slave) | ||

| LAN, VGA, Encoder (two-axis) | |||

| DC input (A dedicated AC adapter is used.) | |||

| Earphone microphone (JEITA RC-5240) | |||

Applications

Measurement of induction hardened layer depth

- Wind power facilities and construction machinery :Swivel bearings

- Automotives and vessels :Crank shafts, gears, shafts, etc.

- And other induction hardened products