Non-destructive test - Magnetic particle testing (MT)

Detection surface and slightly subsurface defects by MT

Magnetic particle Test (MT) is a one of non-destructive test, which can detect surface and slightly subsurface defects of material, machine parts, welding and so on. It can detect of surface and slightly subsurface defects based on indication of particle pattern which is appeared on the test piece.

Process of MT is the following. Magnetic flux at test piece is occurred by magnetization of test piece. Magnetic flux is leaked due to occurrence of N pole and S pole, if there is any defect at the test piece. When ferrous particle is spread on the test piece, leaked magnetic flux attracts ferrous particle at the area of defect, and particles forms what is known indication. Indication can be judged according to criteria.

It shall be selected proper method under the assumption of size of test piece, expected defects, test condition and so on.

Due to above advantage, MT is applied various industry item such as automobile, marine, aviation, pipeline, gas plant, power plant and so on.

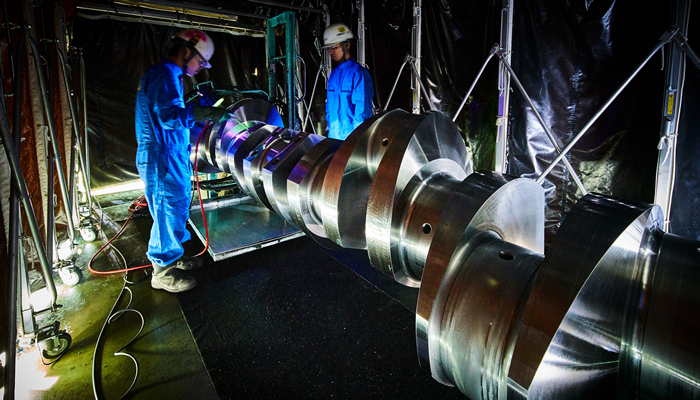

- Inspection for crankshaft by MT

The followings are strong advantage of us.

We can apply established automatic process from magnetization to spray of ferrous particle for the sake of bias decrease.

We have licensed inspectors (JIS, SNT-C1A), who has experience of inspection of various materials - steel, casting, forging, and so on.

We can provide proper inspection according to demand of customer, because our inspector has variable knowledge about not only industrial codes and regulations but also maintenance of equipment.